Teflon Powder

In the realm of friction reduction, few substances hold as much promise as Teflon powder. Renowned for its remarkable properties, this versatile material has revolutionized industries ranging from automotive to aerospace, offering a potent solution for combating friction and enhancing performance.

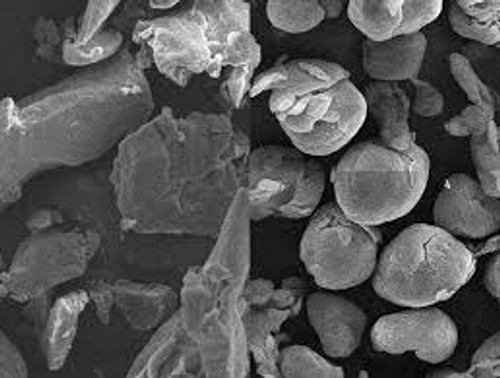

At the heart of Teflon powder's effectiveness lies its unique molecular structure. Composed of long chains of carbon and fluorine atoms, Teflon exhibits an exceptionally low coefficient of friction, making it an ideal candidate for reducing friction between surfaces. When applied as a lubricant in powder form, Teflon particles interpose between contacting surfaces, creating a smooth, low-friction interface that minimizes wear and tear.

One of the key advantages of Teflon powder is its ability to operate across a wide range of temperatures. Whether subjected to extreme heat or cold, Teflon maintains its lubricating properties, ensuring consistent performance in diverse environments. This thermal stability makes it invaluable for applications where temperature fluctuations are common, such as in automotive engines or industrial machinery.

Furthermore, Teflon powder boasts excellent chemical inertness, resisting degradation and maintaining its integrity even in harsh operating conditions. This resistance to chemical attack ensures long-lasting lubrication and protection against friction-induced damage, prolonging the lifespan of critical components and reducing maintenance costs.

Additionally, Teflon powder is non-reactive with most metals and materials, making it compatible with a wide range of surfaces. Whether applied to steel, aluminum, or plastic, Teflon forms a durable, low-friction coating that facilitates smooth motion and minimizes energy loss due to friction.

Moreover, Teflon powder is inherently non-stick, preventing the buildup of debris and contaminants on lubricated surfaces. This self-cleaning property further enhances its effectiveness as a friction-reducing agent, ensuring consistent performance over extended periods.

In conclusion, Teflon powder stands as a testament to the power of innovation in the fight against friction. Its unique combination of low friction, thermal stability, chemical inertness, and non-stick properties makes it a versatile solution for improving performance and efficiency across various industries. By harnessing the friction-reducing wonder of Teflon powder, manufacturers and engineers can unlock smoother operation, reduced wear, and enhanced longevity in their equipment and machinery.